Dewaxing is a crucial step in the edible oil refining process, focusing on removing waxy components from oils to improve their clarity and stability. Wax primarily originates from the plant waxes in the raw oil; if not effectively removed, it can easily lead to cloudiness, precipitation, and negatively impact market competitiveness. Scientific dewaxing significantly lowers the cloud point of oils, allowing them to remain transparent and stable at low temperatures. This not only extends shelf life but also optimizes taste, meeting consumer demand for high-quality edible oils and helping companies improve oil quality.

Dewaxing is typically achieved through a winterization system. The core principle is to control the temperature to reduce the precipitation of wax crystals in the oil, which are then removed by filtration or centrifugation. Key process parameters include cooling temperature, cooling rate, crystallization time, and filtration pressure.

The recommended cooling temperature range is 5°C to 15°C , with the specific value depending on the type of raw oil. The cooling rate should be maintained at a decrease of 3°C to 5°C per hour to ensure uniform wax crystal formation. The crystallization time is usually maintained between 4 and 8 hours to avoid wax residue if it is too short, and reduced production efficiency if it is too long. The filtration process uses a pressure differential control of 0.8-1.5 bar to balance filtration efficiency and equipment safety.

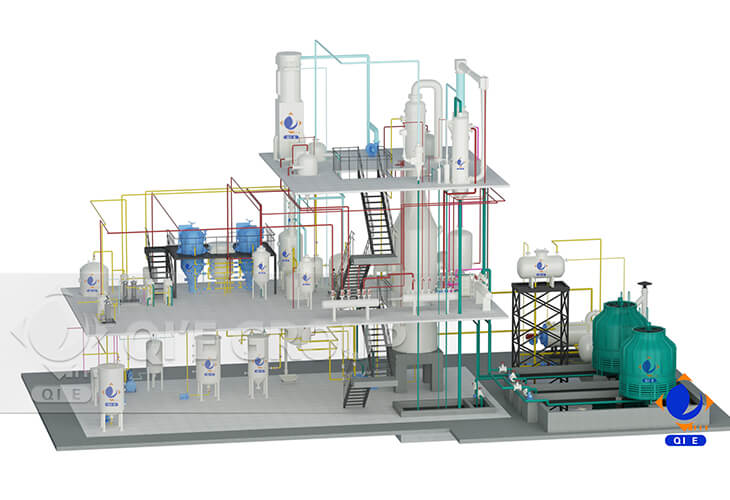

By adopting advanced QIE GROUP dewaxing equipment, these parameters can be controlled more precisely, improving the overall stability and controllability of oil refining, further reducing the risks of manual operation, and increasing the level of production automation.

Dewaxing technology is directly related to several important quality indicators of oils and fats:

A large edible oil processing company applied QIE GROUP's winterization dewaxing system, achieving a 28% increase in oil transparency, a 35% increase in stability, and a 12% increase in processing efficiency. Their success includes:

Common challenges during dewaxing include incomplete wax crystal precipitation or low filtration efficiency. It is recommended to address these issues by optimizing cooling time and increasing filtration differential pressure. Additionally, technical training provided by Tencent should be combined to ensure that operators accurately grasp the key points of the process.

We adhere to relevant national and international standards (such as ISO 6721 edible oil quality standard and GB/T 5009.6 food safety standard) to establish clear indicators for the dewaxing process, ensuring that our oil products meet food safety and quality requirements and enhancing market trust. Furthermore, we implement strict operating procedures and safety regulations to avoid potential health risks from wax components and improve brand reputation.

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)