Dust collecting Dust collecting

↑ ↑

Shea butter kernel → cleaning → Stoning → Magnetic separating →

Crushing → Roasting → Pressing → Crude oil Filtering

↓ ↓

Cake warehouse Refining

↓

Finished Shea Butter

2) .Main process description:

Cleaning sieve

In order to effectively achieve the cleaning effect, ensure a good operating environment and production stability, and improve the quality of finished products, the process is equipped with a high-efficiency vibrating screen to clean up large and small impurities.

Gravity Stoner

Equipped with suction type specific gravity stone remover to remove side stones and side mud

Magnetic Separator

Configure a non-powered magnetic separator to remove iron impurities

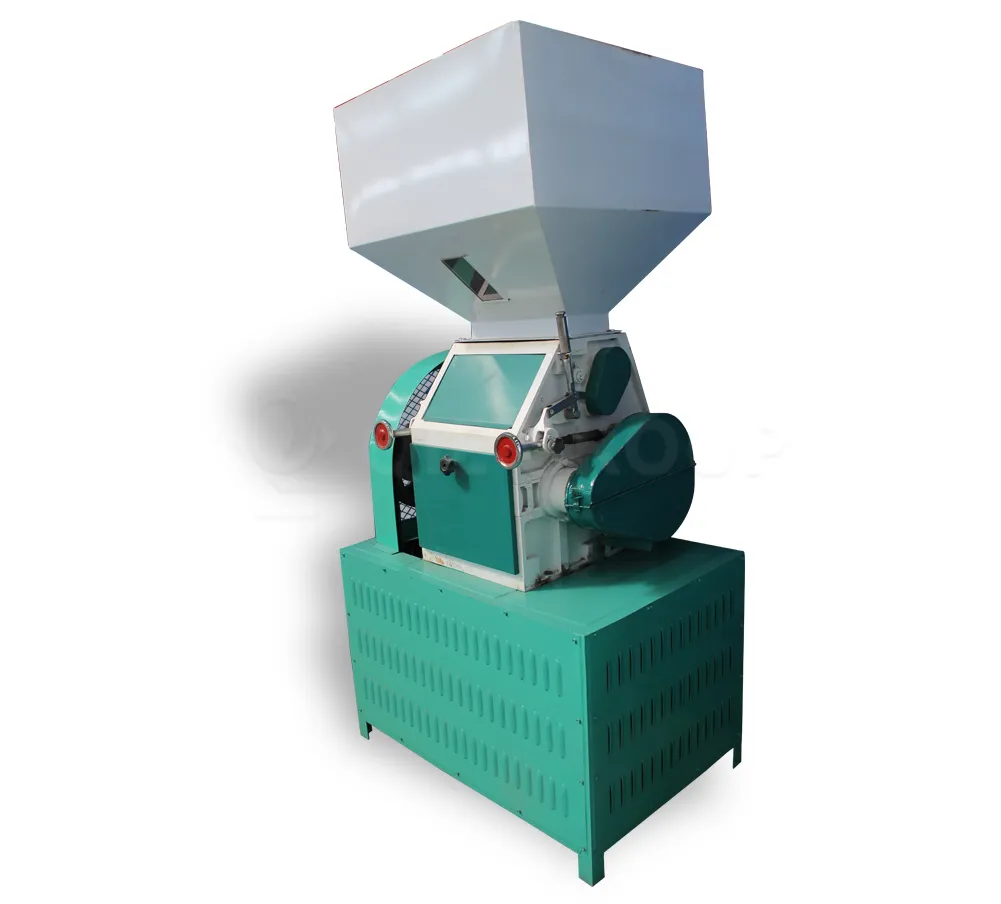

Roller Crusher

In order to ensure good softening and steaming effects, shea kernels are generally evenly broken into 2-6 pieces, and during steaming and frying, the temperature and moisture are evenly distributed, which is convenient for subsequent pressing.

Steaming pan

This process adjusts the moisture and temperature of the peanuts to the appropriate range for easy pressing.

Screw oil press

The screw oil press can squeeze shea nuts, peanuts, rapeseed, sesame, sunflower and other vegetable oils. This model adopts the process of combining round bars and rows, equipped with micro-electric control, infrared heating and multi-stage pressure. It is an ideal equipment for oil processing.

Decanter centrifuge

This machine is a three-phase separation equipment, which uses different separation factors of heavy phase liquid to separate water, oil and residue and discharge them separately. It has strong stability and large processing capacity.

Vertical leaf filter

This machine is an efficient filtering system that uses a thick stainless steel mesh screen to remove coarse and fine residues in the oil and can automatically discharge the residue. The operation is convenient and continuous, with low labor intensity, and is convenient for subsequent fine filtering.

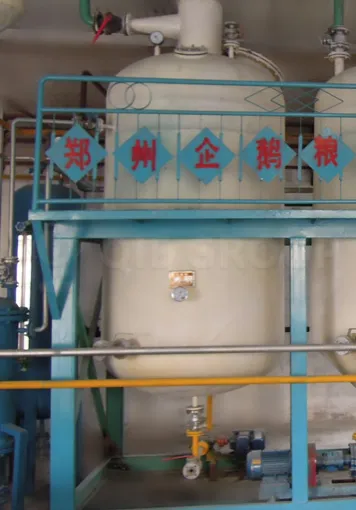

Refining system

After the crude oil is filtered, it is preheated and a certain amount of hot water is added to remove the gum impurities. A certain amount of alkali solution is added to the degummed crude oil for alkali refining reaction, and then the soap stock and neutral oil are separated. The neutral oil after soap removal is washed and separated, and then enters the decolorization pot for heating, vacuum drying and dehydration, and then decolorization and filtration. The decolorized oil enters the deodorization pot, and after deodorization, it is filtered and cooled to the finished oil tank.

Refining Pot

During chemical refining, at a temperature of 60-70°C, sodium hydroxide is used to produce an acid-base neutralization reaction, and the oil is stirred by a reducer to reduce the acid value in the oil, and the impurities and phospholipids are quickly separated and precipitated into the soapnut pot, and then the oil is refined.

Decolorization pot

Also known as a decolorizing and dehydrating pot, it uses steam heating to first remove moisture from the oil under vacuum. Then the clay is sucked into the decolorizing pot through vacuum, stirred, and then filtered out through a vibration filter, thereby achieving the effect of changing the color of the oil.

Vertical leaf filter

The bleaching clay in the oil decolorization section is filtered by a high-efficiency vertical leaf filter, which has the advantages of easy operation, continuous operation, low labor intensity, good environmental conditions, and less residual oil in the waste bleaching clay.

Deodorizing pot (all stainless steel)

The qualified decolorized oil enters the deodorizing pot and is heated to 240-260℃, which is mainly used to remove odor components such as free fatty acids. After the oil in the deodorizing pot is cooled, it is released and passed through a safety filter to finally obtain qualified finished oil.