1. Pretreatment workshop

Soybean--Measuring and cleaning--Softening and conditioning--Secondary dehulling--Flagging--Puffing--Flagging---Drying

Cleaning process

Screening can only remove impurities that are greatly different from the raw material size. For impurities that are not much different from the raw material size, wind separation, magnetic separation and stone removal equipment are required to remove impurities that are lighter or heavier than the raw material.

Softening and Modulation Process

In this process, steam is used to heat soybeans slowly through indirect heating of the heating flat tubes. After feeding from the top, the soybeans contact the heating flat tubes from top to bottom by their own weight, the temperature rises, the internal moisture gradually gathers on the surface, and the bean skin is softened. The water vapor and part of the bean skin are sucked out by the suction device. If the soybeans have a high moisture content, the air can be heated by the auxiliary heater and then enter the heater through the ventilation layer, directly contacting the soybeans to moderately dry the soybeans.

Crushing and peeling process

The crushed beans enter the regulator, and after the bean kernels and bean skins are loosened, the skins and kernels are separated by wind force due to the different specific gravity.

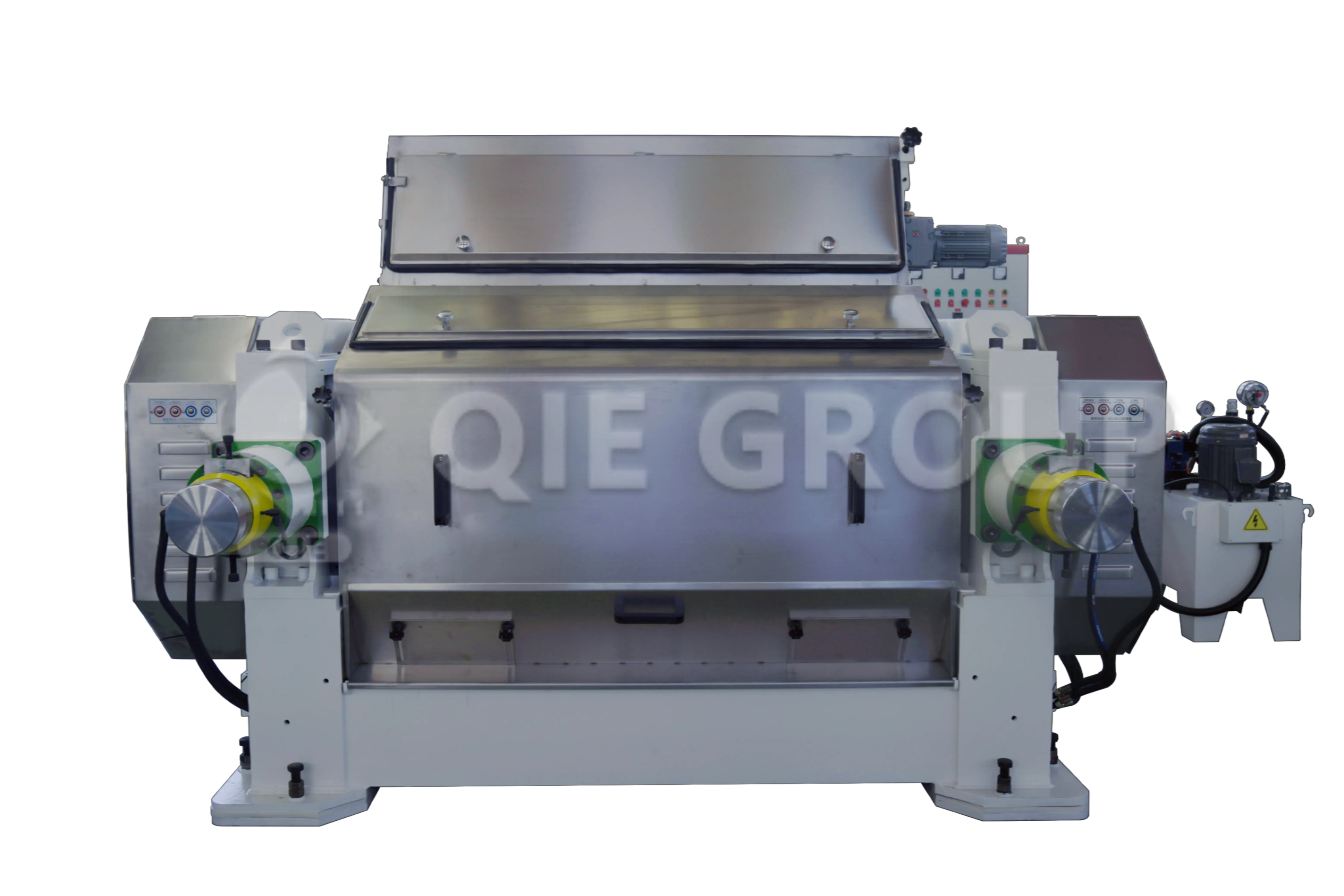

Flaking process

Blank thickness requirements

Thin and uniform, small powder, no oil

Hold your hands and let them loosen, then let them go.

Thickness of embryonic sheet: between 0.3mm and 0.35mm

Low powder content

Extrusion system

The use of an extruder can not only increase the oil yield, but also reduce energy consumption.

Through this process, on the one hand, the solute lipase in the soybean can be passivated under high temperature and high pressure conditions to prevent the soybean oil from becoming rancid; on the other hand, this process can make the soybeans into porous material particles, increase the bulk density of the material, and thus improve the permeability and leaching rate of the reaction between the solvent and the material.

The extraction workshop is a process of extracting crude oil from soybeans obtained from the pre-treatment and drying workshop using n-hexane. The production process includes four steps: extraction, wet meal steaming, mixed oil evaporation, and solvent recovery.

Wet meal desolventizing system

Completely remove the solvent from the meal, reduce solvent loss, and ensure the safe use of the meal;

Passivate and destroy harmful toxins and anti-nutritional components in meal, and improve the quality of meal;

Control and adjust moisture to meet storage and customer requirements.

Taking advantage of the fact that the evaporation temperature of the solvent is much lower than that of water, high-temperature desolventizing is performed, that is, direct steam is used to pass through the material layer, and the two are in contact and heat transfer, causing the solvent to boil and evaporate.

Solvent Recovery System

We recover the solvent through a series of condensers, so that the volatilized gaseous solvent becomes liquid solvent, and the captured solvent is sent to the underground solvent storage tank. The waste gas is sent to the paraffin absorption tower to reduce solvent consumption and pollution. Finally, the waste gas is discharged into the atmosphere.

Exhaust gas recovery system

The air and steam escaping from the solvent condenser and other parts of the leaching plant pass through a final paraffin oil recovery system to remove the solvent before they are discharged into the atmosphere. The paraffin oil recovery system is usually completed by "washing" the steam with mineral oil-paraffin oil in an absorption tower. For economic and safety reasons, an effective solvent recovery system must be used.

Soybean oil refining process

The purpose of oil refining

Remove harmful substances and impurities to the human body

Improve the taste and appearance of oil products

Good for long-term safe storage

Neutralization section:

Heat the crude oil to about 75°C;

Indirect steam heating; heat exchange with hot oil (normal operation)

Acidification: The main purpose is to convert the non-hydratable phospholipid molecules in the oil into hydratable phospholipid molecules (degumming)

Adding alkali: The main purpose is to generate soap with free fatty acids (deacidification)

Centrifugal separation: Alkali reacts with free fatty acids in crude oil to form soap, which has a certain adsorption effect and can adsorb some substances;

Add water: mainly add soft water to wash the residual soap. During this period, add appropriate amount of phosphoric acid to prevent oil emulsification. The water washing temperature is controlled at 85-90℃;

dry

Decolorization section

It mainly removes pigments in oil, removes residual trace soap particles, phospholipids and other colloids and some odorous substances, removes polycyclic aromatic hydrocarbons and residual pesticides, etc.

Purpose of deodorization section:

Remove odorous substances, increase the smoke point of oil, improve oil stability, color, quality, remove fatty acids, peroxides, polycyclic aromatic hydrocarbons, residual pesticides, etc.