Metering process: special equipment is used, and the metering scale has stable production, which is used to adjust the flow and measure the total production volume, and can achieve the purpose of cumulative metering, instantaneous metering and cost accounting, with accurate metering and high precision.

Cleaning process: Use magnetic separator to remove iron impurities; vibrating cleaning screen to remove large impurities, straw, etc.; gravity stone remover to remove heavy impurities such as stones and bricks; the dust removal system uses single-unit brake and centrifugal fan for effective dust removal to ensure workshop hygiene and remove light impurities.

.webp)

Softening process: The material enters the softening drum through the feeding auger. As the drum rotates, the material is constantly turned. Since the drum is equipped with heating tubes and steam is passed through the tubes, the material is heated to 50-70℃ as the drum is constantly turned, so that the soybeans are fully softened, the plasticity of the soybean raw materials is improved, and the embryos rolled out by the embryo rolling machine are thin but not broken, thereby improving the leaching effect. The drum has a high inclination at the feeding end and a low inclination at the discharging end. According to the softening condition of the material, the speed of the drum can be adjusted through the speed regulating device to control the softening time of the material in the drum, so that the softening effect of the material can be optimal.

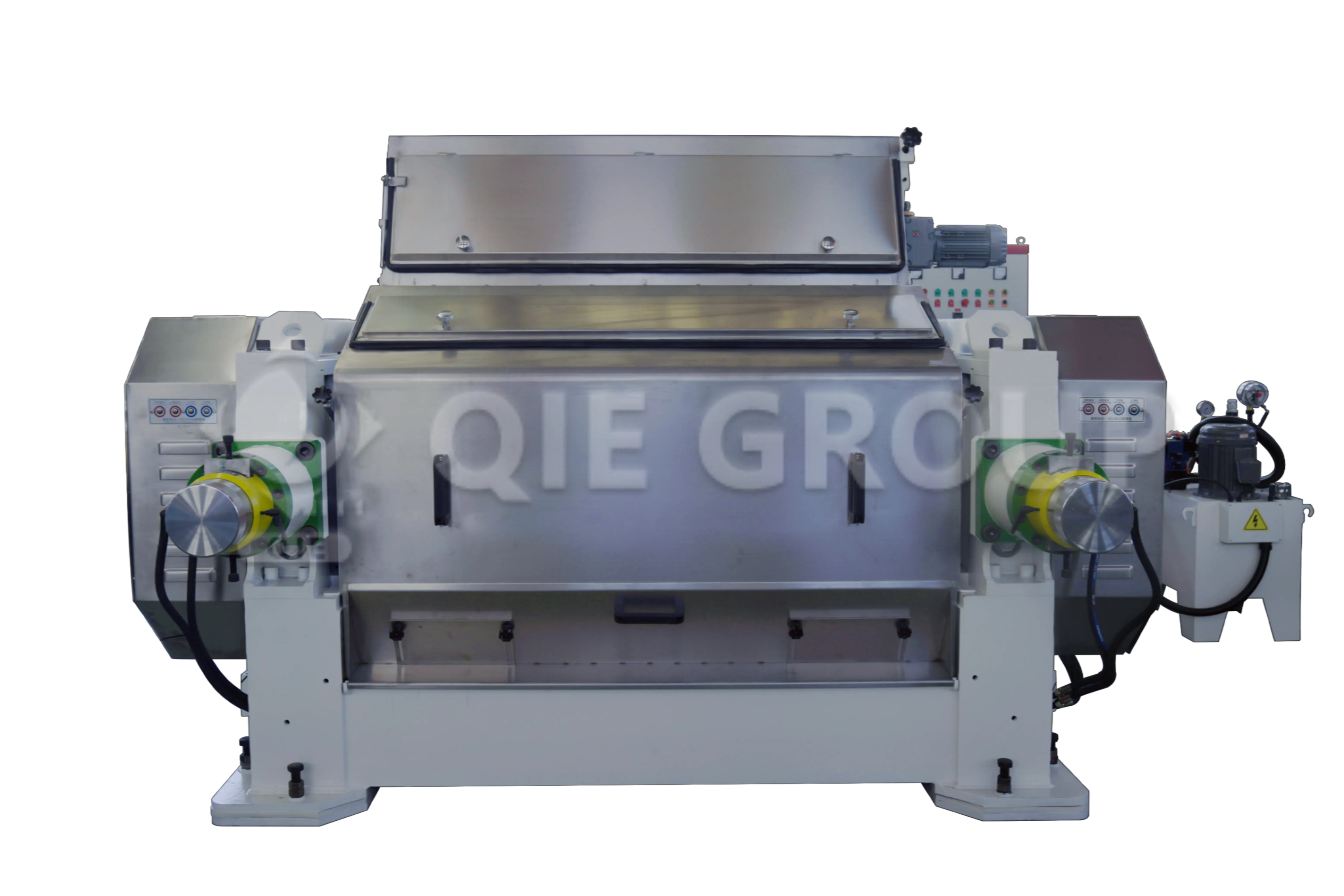

Flaking process: hydraulic tight roller flaking machine is used to better destroy the oilseed cell tissue to ensure that the flaking sheet is thin and uniform, tough and has little powder.

Puffing process: The oilseed embryo flakes are subjected to mechanical actions such as extrusion, kneading, shearing, and pressurization in the puffing machine, as well as a series of physical and chemical actions such as the moist heat effect of the injected steam and the heating effect of friction. The cell tissue of the oilseed is completely destroyed, and the enzymes in the oilseed are passivated. When discharged from the outlet of the extrusion puffing machine, the high-temperature and high-pressure material is instantly transformed from high pressure to atmospheric pressure, causing moisture to be quickly released from the material structure, and the material is then puffed and formed, thereby obtaining a loose and high-strength extruded puffed material.

Drying process: Main structure: The upper part is equipped with an air lock to prevent short circuit of the drying airflow. A material distribution device is installed below the outlet of the air lock, which adopts a worm gear box reduction mechanism and an automatic self-aligning coupling, and operates smoothly and reliably, so that the granular materials can be evenly distributed in the intermediate bin. Two material level devices are set in the intermediate bin, and they form an electrical interlock control with the discharge mechanism. The hydraulic flap discharge system discharges materials evenly, the mechanism is safe and reliable, and maintenance is convenient. The proximity switch at the flow control device is used to adjust the opening of the hydraulic flap, and a total emptying button is provided to discharge the material after shutdown to prevent particles from remaining in the intermediate bin and causing adhesion.

The complete set of pretreatment workshop equipment we provide has the following advantages :

The process of tempering, crushing, secondary peeling and puffing is adopted; all operations are continuous and mechanized; it is equipped with an electrical interlocking control system; it adopts a computerized automatic control system, and the computer displays, controls and records. The workshop has an independent control room for centralized control; it has a large-screen analog control panel with automatic alarm and interlocking control; temperature, pressure, material level and flow automatic control instruments to ensure that the operation of the workshop can be understood and controlled in the control room. It is equipped with a powerful dust removal system to meet the needs of production and environmental protection; it is equipped with an automatic control high-efficiency temperature peeling system with low energy consumption and high peeling rate; the material can be bypassed when not peeling; the impurities removed can be crushed and added back to the meal, or they can be stored and transported in a centralized manner; in order to ensure the hygiene and beauty of the workshop, the equipment insulation is all covered with colored steel plates.